Castable

Home | Products/Applications | Specialty Refractory Products |

Loose refractory materials that cure in place to form custom insulating structures. Perfect for field repairs, unique geometries, and applications requiring seamless thermal barriers.

Product Applications

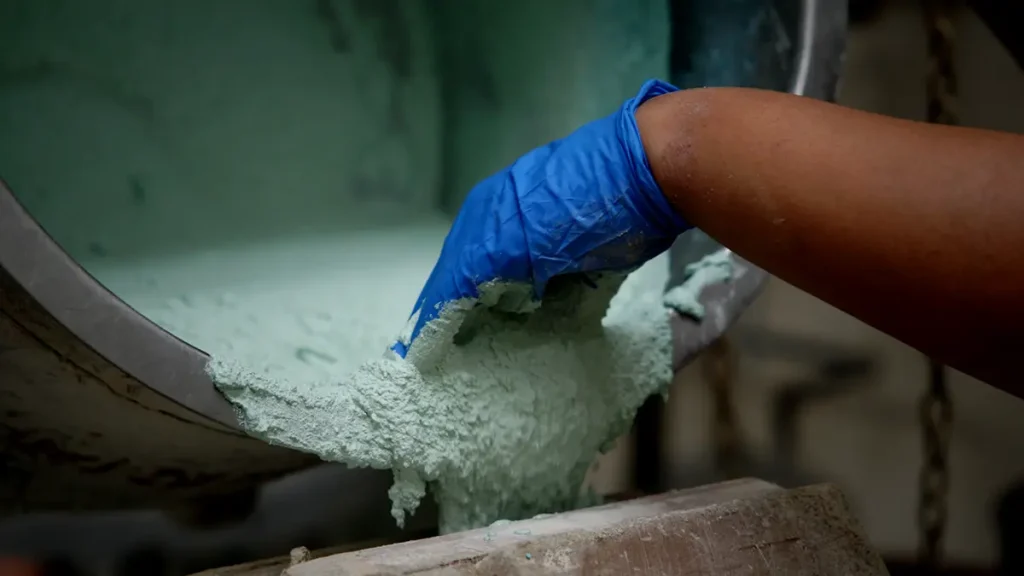

When your application demands another level of customization and flexibility, Zircoa castable refractory materials provide the solution. These loose, wet-form materials allow you to create custom shapes, repairs, and complex geometries directly at your facility, offering unmatched design freedom for unique furnace configurations and field applications.

Unlike pre-fired or pre-sintered products, our castable refractory materials cure and develop their properties in place, enabling seamless installations and perfect conformity to any geometry. Zircoa provides the specialized “cement” formulations along with expert guidance on proper mixing, application, curing, and heat treatment procedures.

Our selective approach ensures you receive exactly the right castable refractory composition for your specific application, backed by our decades of expertise in refractory material science. Learn more below, or reach out to our team for more information.

The Benefits of Zircoa Castable Refractory Materials

- Ultimate customization for any geometry or configuration

- On-site forming eliminates shipping constraints for large components

- Seamless installation with no joints or assembly requirements

- Perfect conformity to complex shapes and existing structures

- Field repair capabilities for emergency maintenance

- Multiple composition options for specific performance requirements

- Expert guidance on mixing, application, and curing procedures

- Cost-effective solution for unique or one-off applications

Primary Industries

- Glass manufacturing with complex furnace geometries

- Chemical processing plants with specialized reactor configurations

- Power generation facilities needing custom insulation solutions

- Industrial furnace manufacturers and rebuilders

Key Applications

- Custom furnace linings and complex geometrical configurations

- Field repairs and emergency maintenance applications

- Specialized reactor linings for chemical processing

Castable Refractory Material Selection and Application

Our refractory specialists work with you to select the optimal castable composition based on:

- Operating temperature requirements and thermal cycling conditions

- Chemical exposure and atmosphere compatibility

- Mechanical stress and structural requirements

- Installation methods and curing constraints

Proper castable application requires expert guidance. Our technical team provides:

- Detailed mixing and application procedures

- Curing schedules and heat treatment protocols

- Quality control recommendations and testing procedures

- Troubleshooting support throughout installation

Typical Properties

| Composition | 0871 | 0876 | 0880 |

|---|---|---|---|

| Stabilizer | CaO | CaO | CaO |

| Typical Chemistry | |||

| SiO2 (wt.%) | 0.4 | 0.3 | 0.3 |

| CaO (wt.%) | 2.4 | 2.8 | 3.6 |

| MgO (wt.%) | 0.4 | 0.1 | 0.1 |

| Fe2O3 (wt.%) | 0.1 | 0.1 | 0.1 |

| Al2O3 (wt.%) | 0.4 | 1.3 | 1.5 |

| TiO2 | 0.2 | 0.1 | 0.1 |

| Y2O3 (wt.%) | N/A | N/A | N/A |

| Typical Physical Properties | |||

| Density (g/cm3) | 3.3 | 4.7 | |

| Porosity (%) | 37.0 | 15.0 | |

| Cold MOR (Mpa) | 5.0 | ||

| Monoclinic (%) | 53 | 30 |

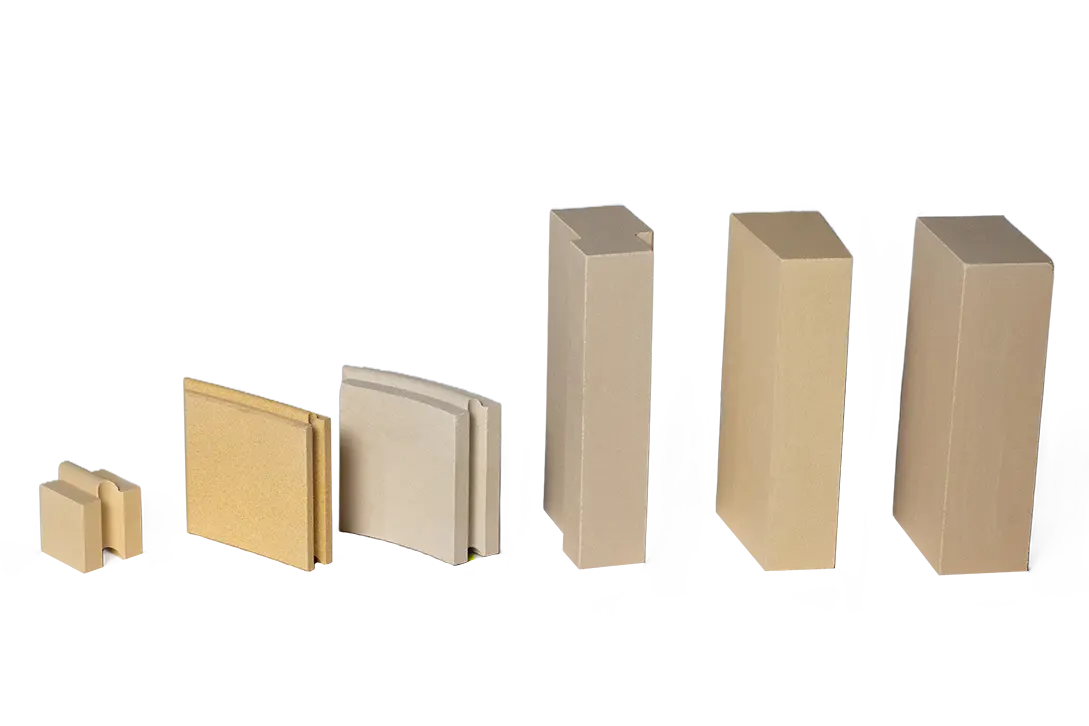

Castable Refractory Systems

Combine castable materials with our standard brick, custom shapes, and backup insulation for a complete refractory system. Our castables provide the flexibility to create seamless transitions and perfect fits within existing furnace structures while maintaining optimal thermal performance.

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Klaus Steuer

+49-160-92364181