Custom Shapes

Home | Products/Applications | Specialty Refractory Products |

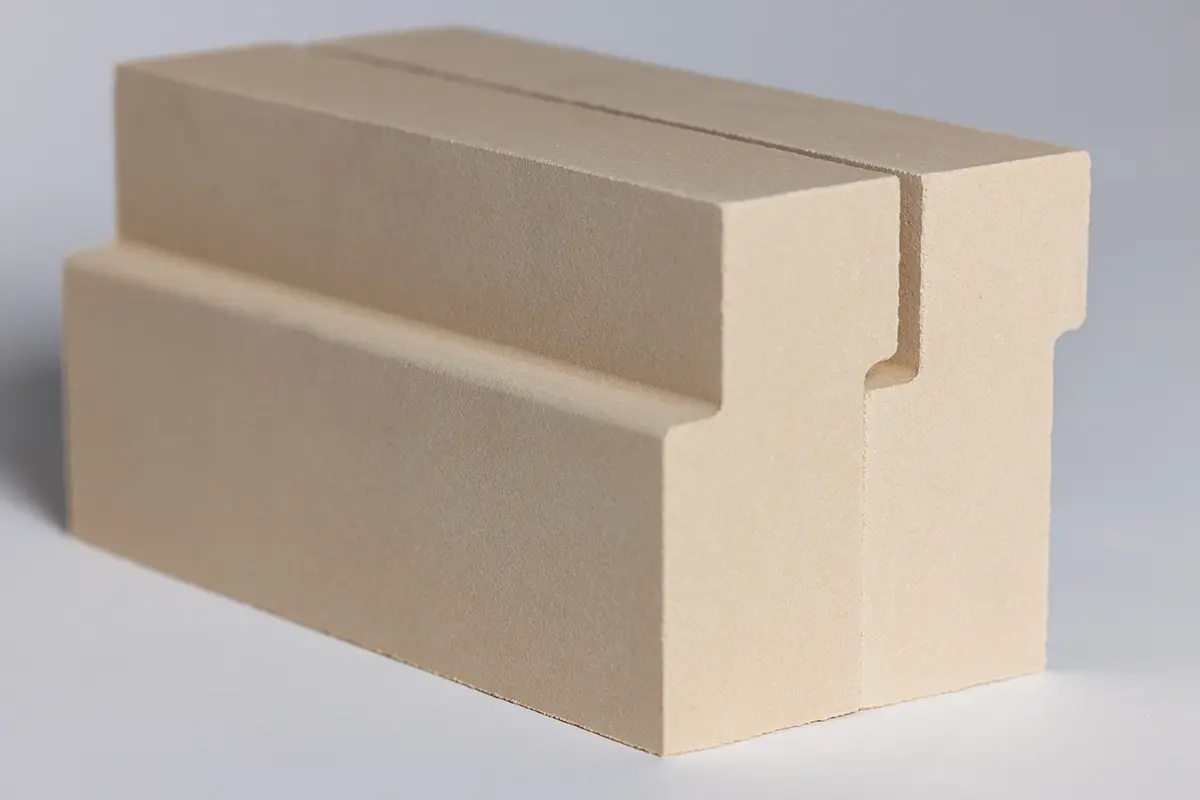

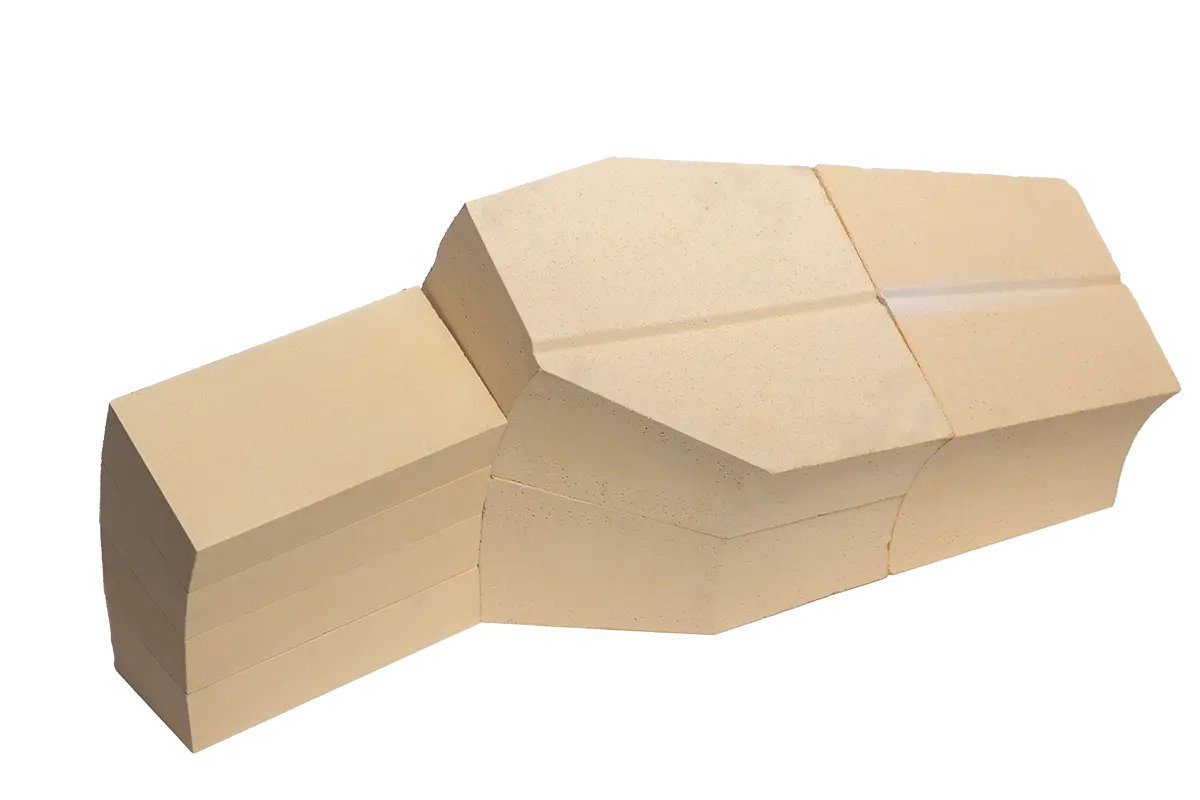

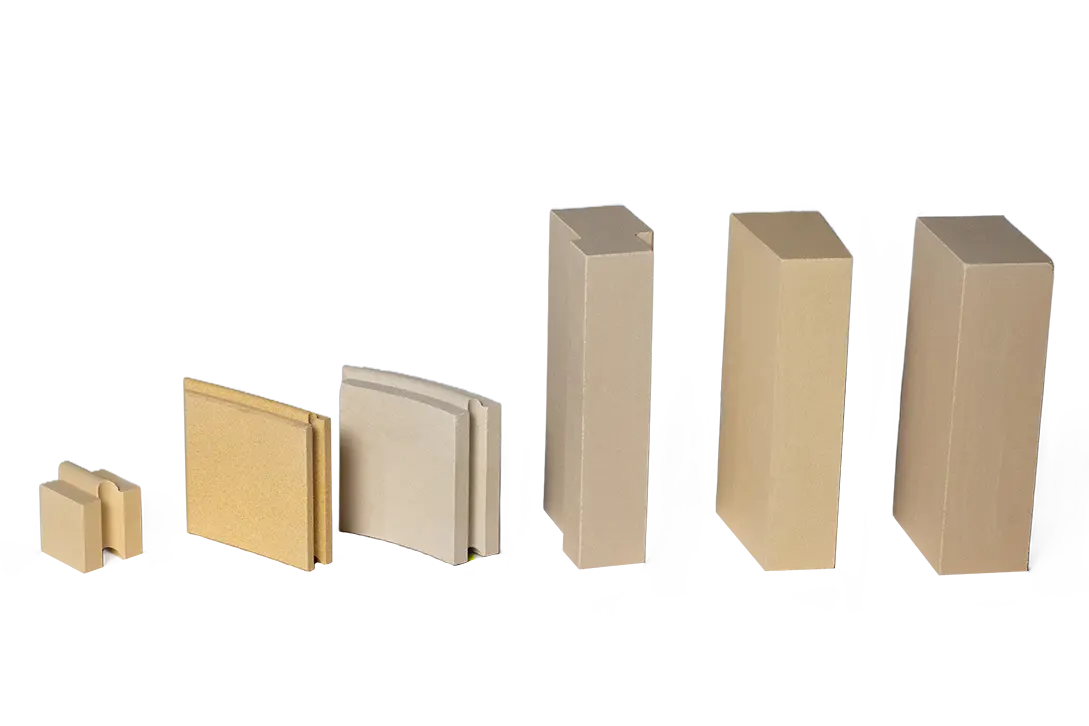

Engineered pre-formed and fired shapes designed to optimize installation and insulation for unique furnace geometries and specialized applications. From simple blocks to complex configurations, our custom solutions solve challenging design and performance requirements.

Product Applications

When standard brick configurations can’t meet your unique furnace geometry or application requirements, Zircoa custom shapes provide the precise refractory lining solutions you need. Our pre-formed, pre-sintered custom refractory components are engineered to your exact specifications, offering superior forming methods and optimized physical properties for demanding applications.

These advanced custom shapes serve as high-performance replacements for traditional burner blocks while expanding capabilities far beyond glass furnaces into carbon black production, electronics manufacturing, energy systems, and medical applications where precision and reliability are critical. With Zircoa refractory lining, either Calcia, Yttria, or Magnesia-stabilized zirconium oxide compositions help extend burner block life, withstand high temperatures and contaminants present in fuel oil.

Learn more about this offering below, or contact our service representatives to discuss specific requirements.

The Benefits of Zircoa Refractory Lining

- Pre-formed and pre-sintered for consistent performance

- Custom geometries engineered exactly to your specifications

- Superior forming methods for complex configurations

- Optimized physical properties for specific applications

- Enhanced thermal shock resistance for reliable cycling

- Chemical resistance against aggressive process atmospheres

- Dimensional precision for perfect fit and sealing

- Extended service life reduces maintenance and downtime

Primary Industries

- Carbon black production and processing facilities

- Electronics manufacturing and semiconductor processing

- Energy systems and power generation applications

- Medical device manufacturing and pharmaceutical processing

- Glass furnaces and high-temperature melting operations

Key Applications

- Custom burner block replacements for enhanced performance

- Complex furnace geometries requiring precision fit components

- High-temperature process equipment with unique configurations

- Specialized refractory lining systems for aggressive environments

- Critical applications where standard shapes cannot perform

Custom Shape Design and Engineering

Comprehensive Design Support

Our engineering team collaborates directly with you to design custom shapes tailored to your unique application needs and performance challenges.

- CAD design and finite element analysis

- Material selection optimized for your operating conditions

- Forming method selection for optimal properties

- Installation guidance and technical support

Typical Properties

| Composition | 0871 | 0872 | 0874 | 0880 | 0890 |

|---|---|---|---|---|---|

| Stabilizer | CaO | CaO | CaO | CaO | Y2O3 |

| Typical Chemistry | |||||

| SiO2 (wt. %) | 0.4 | 0.3 | 0.3 | 0.3 | 0.2 |

| CaO (wt. %) | 2.4 | 2.4 | 2.4 | 3.6 | 0.1 |

| MgO (wt. %) | 0.4 | 0.4 | 0.4 | 0.1 | 0.4 |

| Fe2O3 (wt. %) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Al2O3 (wt. %) | 0.4 | 0.3 | 0.3 | 1.5 | 0.4 |

| TiO2 (wt. %) | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 |

| Y2O3 (wt. %) | N/A | N/A | N/A | N/A | 6.0 |

| Typical Physical Properties | |||||

| Density (g/cm3) | 3.3 | 3.8 | 4.0 | 4.7 | 4.0 |

| Porosity (%) | 37.0 | 33.0 | 30.0 | 15.0 | 30.0 |

| Cold MOR (Mpa) | 5.0 | 5.5 | 10.0 | 16.5 | 5.5 |

| Monoclinic (%) | 53 | 50 | 48 | 30 | 50 |

Complete Custom Refractory Solutions

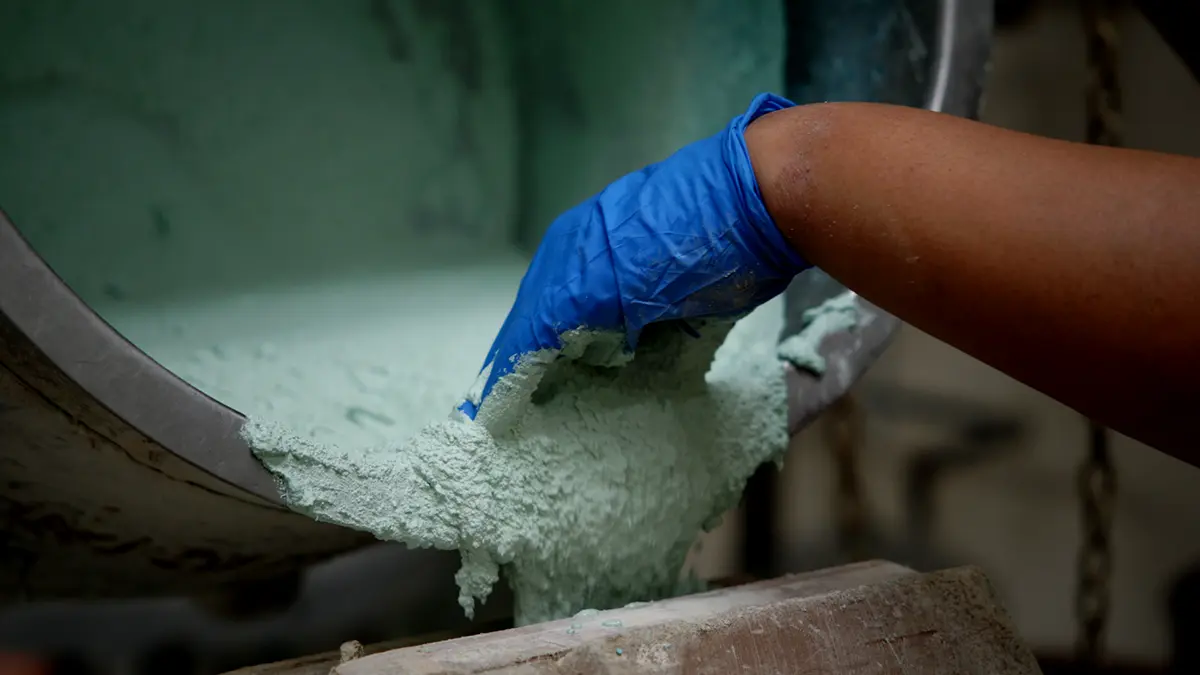

Extend the life of your furnace and maintain better control over your furnace temperatures with Zircoa’s pre-sinstered grog refractory backup. Options include:

- Backup 1859 — Grog, partially stabilized with magnesia and calcia

- Backup 1860 — Grog, partially stabilized with magnesia and calcia

- Backup GNF — Grog, partially stabilized with calcia

- Backup 10B — Bubble, partially stabilized with calcia

Integrated System Approach

Combine custom shapes with our standard brick, castable materials, and other specialized components for complete refractory systems engineered for your unique requirements. Our comprehensive approach ensures optimal thermal performance and extended service life.

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Klaus Steuer

+49-160-92364181