Find the Right ZrO₂ Products for Your Specific Application

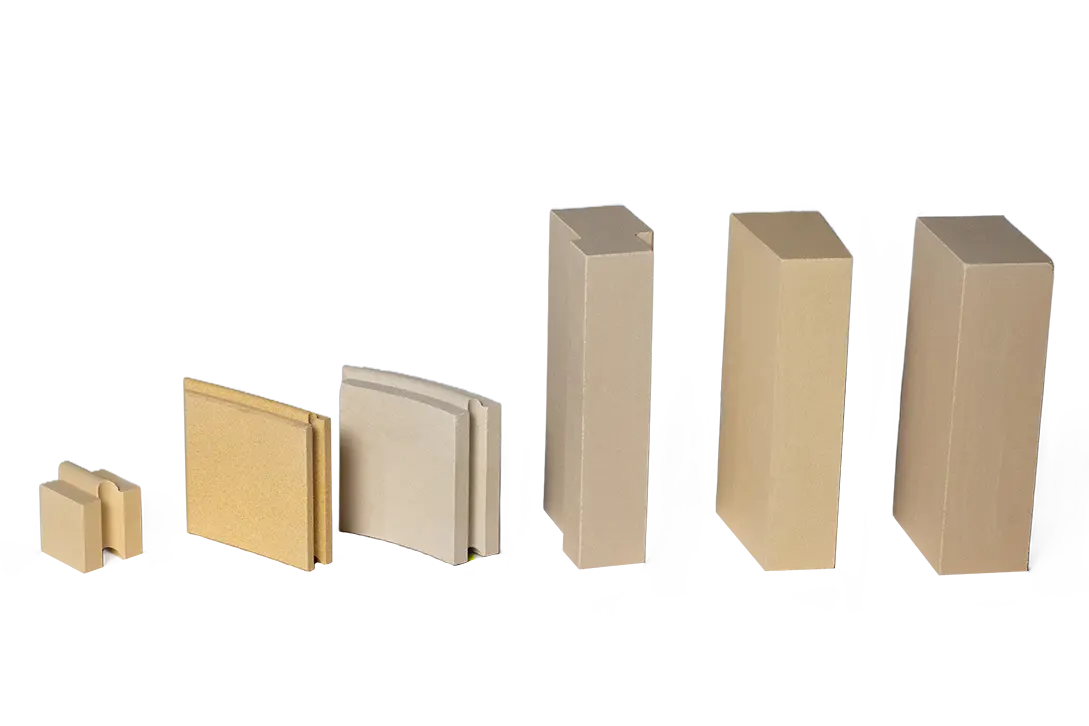

Zircoa manufactures three distinct categories of zirconia products, each engineered for different performance requirements and operating environments. Whatever your challenge — extreme heat, abrasion, or custom material performance — Zircoa’s ZrO₂ products deliver reliable, application-driven solutions.

Use the filters below to quickly find products by process category or application, or explore our complete product categories to discover solutions you may not have considered. Already know what you need? Connect with our team to initiate your project.