Granular Zirconia (GROG)

Home | Products/Applications | Granular Products |

Pre-sintered refractory backup materials that provide superior thermal insulation and extend furnace life. Available in multiple compositions and mesh sizes for custom insulation and crucible backup applications.

Product Applications

Granular zirconia (grog) serves as essential backup refractory insulation that dramatically improves the energy efficiency and operational life of your high-temperature systems. When used as crucible backup or furnace lining insulation, our pre-sintered granular materials deliver approximately five times the insulating value of traditional alumina or magnesia alternatives, helping you achieve tighter temperature control while reducing energy costs.

This complementary material works alongside Zircoa’s primary refractory products to optimize overall system performance. In crucible applications, granular zirconia extends service life and promotes cleaner melts by providing superior thermal barrier properties and minimizing heat loss through furnace walls.

Learn more about our refractory insulation below, or contact our zirconia experts to discuss your specific crucible backup requirements.

How Granular Zirconia (Grog) Outperforms Alternatives

- 5x more effective than alumina or magnesia backup materials

- Reduces thermal stress on primary refractory components

- Minimizes heat loss for reduced operating costs

- Maintains tighter, more consistent furnace temperatures

- Reduces contamination risk in melting applications

- Engineered to withstand extreme temperature cycling

- Available in multiple stabilized compositions for specific environments

- Consistent performance in demanding high-temperature applications

Primary Industries

- Investment casting foundries requiring extended crucible life and energy efficiency

- Aerospace component manufacturing with strict temperature control requirements

- Precious metals processing operations demanding contamination-free environments

- Glass and quartz melting above 1900°C

- Crystal growth operations requiring precise thermal management

- Steel production environments with extreme thermal cycling demands

Key Applications

- Crucible backup insulation for extended service life and cleaner melts

- Furnace lining thermal barriers for improved energy efficiency

- High-temperature insulation systems requiring superior thermal performance

- Backup materials for molten metal contact environments

- Thermal cycling applications in glass and crystal growth operations

- Energy-efficient insulation solutions for steel and aerospace processing

Granular Zirconia Specifications & Selection

Available Stabilization Types

- Magnesia — Molten metal environments and environments subject to extreme wear

- Calcia — Continuous high temperature, or cycling applications with no molten metal contact

Available Compositions

- Zircoa Backup 1859 — Grog, partially stabilized with magnesia and calcia

- Zircoa Backup 1860 — Grog, partially stabilized with magnesia and calcia

- Zircoa Backup GNF — Grog, partially stabilized with calcia

- Zircoa Backup 10B — Bubble, partially stabilized with calcia

Custom particle size distributions and specialized compositions can be engineered to meet specific application requirements.

Typical Properties

| Composition | 1859 | 1860 | Bubble 10B | GNF |

|---|---|---|---|---|

| Stabilizer | CaO | CaO | ||

| Typical Chemistry | ||||

| SiO2 (wt.%) | 0.6 | 0.6 | 0.4 | 0.3 |

| CaO (wt.%) | 3.7 | 3.5 | ||

| MgO (wt.%) | 0.1 | 0.2 | ||

| CaO + MgO (wt.%) | 4.5 | 4.5 | ||

| Fe2O3 (wt.%) | 0.2 | 0.2 | 0.1 | 0.1 |

| Al2O3 (wt.%) | 0.2 | 0.2 | 0.4 | 0.4 |

| TiO2 (wt.%) | 0.2 | 0.2 | 0.2 | 0.2 |

| Y2O3 (wt.%) | N/A | N/A | N/A | N/A |

| Tyler Mesh Size | ||||

| Typical Sizing | -8 / +100 | -8 / +28 | -10 / +28 | Various Sizes |

| Mesh Size (Tyler) | % (max or range) | |

|---|---|---|

| -3+6 | +3 | 10 |

| -3+6 | -3+3.5 | 10-40 |

| -3+6 | -3.5+4 | 20-50 |

| -3+6 | -4+6 | 10-40 |

| -3+6 | -6+8 | 5-35 |

| -3+6 | -8 | 20 |

| -6 Mesh | +6 | 10 |

| -6 Mesh | -6+8 | 10-40 |

| -6 Mesh | -8+14 | 20-50 |

| -6 Mesh | -14+28 | 10-40 |

| -6 Mesh | -28+48 | 5-35 |

| -6 Mesh | -48+100 | 0-25 |

| -6 Mesh | -100 | 30 |

| -8 Mesh | +8 | 1 |

| -8 Mesh | -8+14 | 32 |

| -8 Mesh | -14+28 | 13-45 |

| -8 Mesh | -28+48 | 20-45 |

| -8 Mesh | -48+100 | 43 |

| -8 Mesh | -325 | 11 |

| -14 Mesh | +14 | 0 |

| -14 Mesh | -14+28 | 10-40 |

| -14 Mesh | -28+48 | 15-25 |

| -14 Mesh | -48+100 | 15-30 |

| -14 Mesh | -100+325 | 20-40 |

| -14 Mesh | -325 | 0-10 |

| -28 Mesh | +8 | 0 |

| -28 Mesh | +14 | 0 |

| -28 Mesh | -14+28 | 0-9 |

| -28 Mesh | -28+48 | 27-72 |

| -28 Mesh | -48+100 | 18-36 |

| -28 Mesh | -100+325 | 4-35 |

| -28 Mesh | -325 | 0-10 |

| -100 Mesh | +48 | 1 |

| -100 Mesh | -48+100 | 5 |

| -100 Mesh | -325 | 25 |

| -235 Mesh | +200 | 5 |

| (Wet Screen) | +325 | 15 |

Granular Zirconia Selection and Support

Selecting the optimal granular zirconia composition depends on your specific operating environment, temperature requirements, and chemical exposure conditions. Our application specialists can recommend the ideal stabilization type and particle size distribution for your backup insulation needs.

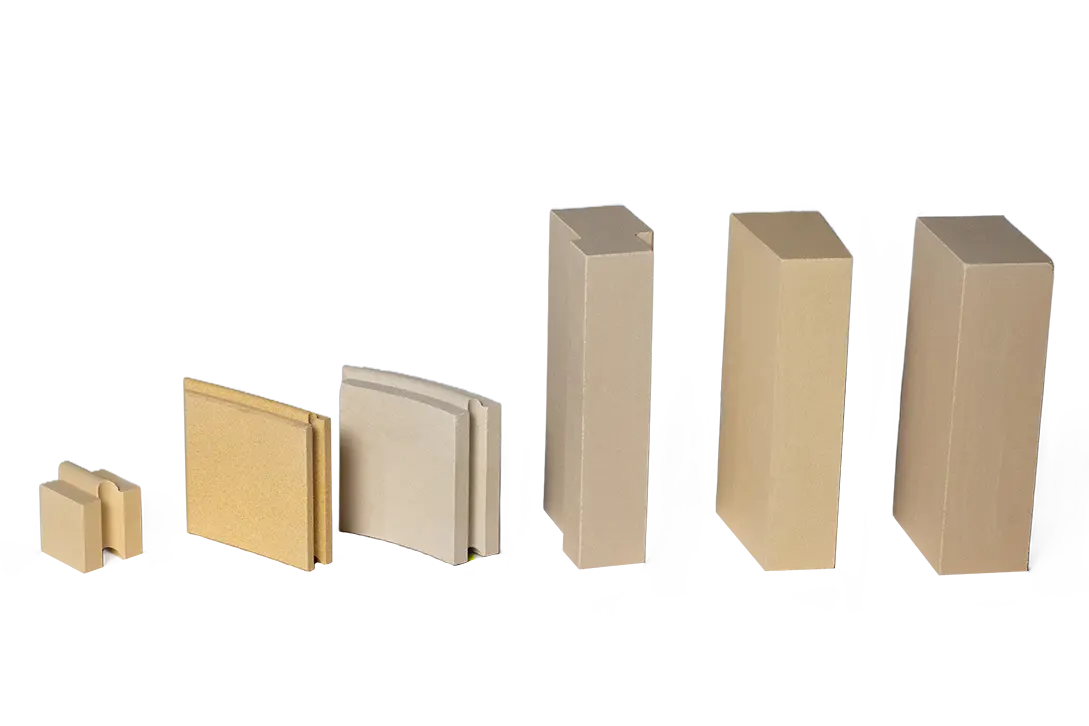

Granular zirconia grog delivers maximum benefits when paired with Zircoa’s zirconia crucibles, bricks, custom shapes, tubes, and other specialty refractory products. This integrated approach ensures optimal thermal efficiency, extended service life, and superior process reliability across your entire high-temperature system.

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Klaus Steuer

+49-611-335497-20