A Grain Zirconia Powder

Home | Products/Applications | Granular Products |

Proprietary high-purity zirconia powder with unique spheroidal particle shape and precisely controlled properties. Essential for oxygen sensors, zirconium metal production, electronic components, and specialized manufacturing applications.

Product Applications

A Grain Zirconia represents a Zircoa specialty and key differentiator in the zirconia market — a proprietary high-purity powder and distinct spheroidal particle shape. This customizable monoclinic zirconia powder is synthesized from zircon sand using our solid-state reaction process, yielding consistently high purity zirconia with unique properties that solve problems conventional zirconia powders cannot address.

Our standard A Grain zirconia powder features a mean particle size of 2.1 microns with exceptional spheroidal particle shape, low surface area (1 m²/g), and superior dispersibility characteristics. These distinctive properties enable critical applications from automotive airbag initiators to asbestos alternatives like chlor-alkali products, representing technologies that impact daily life around the world.

Learn more about our proprietary A Grain zirconia powder below, or contact our specialists to discuss your specific high-purity zirconia requirements.

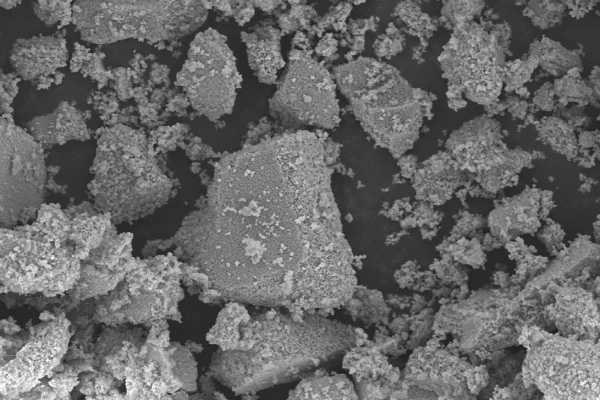

Zircoa A Grain

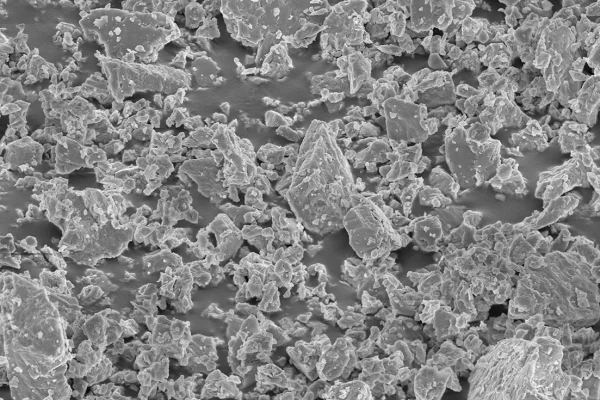

Typical Precipitated Zirconia

Typical Fused Zirconia

Zircoa A Grain: Not an Ordinary Zirconia Powder

- Proprietary spheroidal particle shape unique to Zircoa manufacturing method

- High purity monoclinic zirconia with consistent quality control

- Customizable chemical and physical properties

- Low surface area (1 m²/g) for reduced reactivity and superior flow properties

- Exceptional dispersibility enables uniform distribution in various media

- Consistent 2.1-micron mean particle size for reliable performance

- Easily dispersed with high solids loading capabilities (80-90%)

- Lower shrinkage of fired parts improves dimensional control

- Customizable chemical and physical properties to improve processing and efficiency

Key Applications

- Sensors for oxygen measurement and control

- Zirconium metal production in automotive airbag initiators

- Display glass filler for toughening and durability

- Chlor-alkali processes as a non-asbestos material to enhance health and safety

- Catalyst supports and substrates for chemical processing

- Ceramic colorants and opacifiers for specialized applications

- High-temperature applications requiring thermal stability

Primary Industries

- Automotive

- Chemicals

- Electronics

- Glass

- Refractories and Ceramics

- Steel

A Grain Zirconia Specifications and Properties

Unique Manufacturing Process

Zircoa’s proprietary solid-state reaction process synthesized from zircon sand delivers zirconia powder with properties that conventional precipitation or fusion methods cannot achieve. Our manufacturing approach ensures impurities are controlled and the distinctive spheroidal particle shape enables superior performance.

Critical Performance Characteristics

- Mean particle size: 2.1 microns (by Microtrac analysis)

- Surface area: 1 m²/g (by BET analysis method)

- Particle shape: Unique spheroidal configuration

- Phase composition: Monoclinic

Typical Properties

| ZrO2* | wt.% | 99.6 |

| SiO2 | wt.% | < 0.3 |

| CaO | wt.% | 0.2 |

| MgO | wt.% | < 0.1 |

| Fe2O3 | wt.% | < 0.1 |

| Al2O3 | wt.% | < 0.1 |

| TiO2 | wt.% | < 0.1 |

*includes naturally occurring HfO2 2.5% maximum

Engineering Support for A Grain Zirconia Powder

Our decades of zirconia expertise enable comprehensive support for A Grain applications, from material selection through process optimization. Access our engineering resources and technical support to maximize the unique benefits of our standard, proprietary zirconia powder or customize a solution for your specific application.

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Jake Mochoskay

+1-440-409-4827

Europe, the Middle East, Africa & India

Thomas Boehm

+49-611-335497-22