Coarse Grain Tubes

Home | Products/Applications | Specialty Refractory Products |

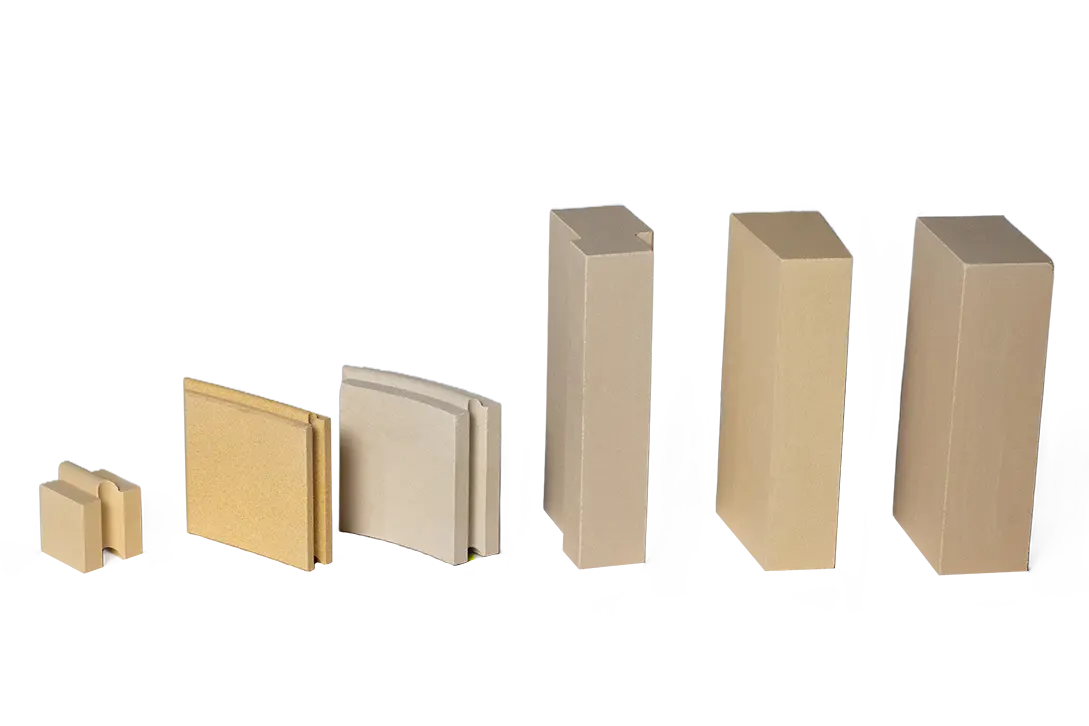

High-temperature tubes for induction heating, crystal growth, and non-reactive firing applications. Available in various sizes, grain structures, and compositions to match your specific thermal and chemical requirements.

Product Applications

Coarse grain tubes from Zircoa are engineered to withstand the demanding thermal cycling environments essential for crystal growth operations and induction heating applications. These precision-manufactured tubes deliver reliable performance in non-reactive firing processes where material purity and thermal shock resistance are critical to success.

Available in both pressed and cast configurations, our coarse grain tubes are manufactured in various diameters, lengths, and compositions to satisfy the unique requirements of your specific application. Whether for crystal growth furnaces or specialized induction heating systems, these tubes provide the thermal reliability needed for consistent results.

Learn more about our crystal growth and thermal cycling solutions below, or connect with our team to discuss your specific requirements.

The Advantages of Zircoa Coarse Grain Tubes

- Superior thermal shock resistance for reliable cycling from room temperature to 2000°C

- Non-reactive properties preserve material purity in sensitive processes

- Engineered porosity optimized for thermal cycling performance

- Multiple grain sizes and configurations for application-specific requirements

- Pressed and cast options to meet different performance needs

- Chemical inertness prevents contamination in high-purity applications

- Extended service life reduces furnace downtime and replacement costs

- Dimensional stability maintains performance through repeated thermal cycles

Primary Industries

- Crystal growth and semiconductor manufacturing

- High-purity quartz processing operations

- Electronic component manufacturing and processing

- Specialty glass and optical material production

- Advanced materials research and development

Key Applications

- High-temperature induction heated crystal growth furnaces and applicable crystal growth methods

- Non-reactive firing of electronic components and ceramics

- Quartz and sapphire crystal growing operations

- Specialty glass forming and processing applications

- Research furnaces requiring contamination-free environments

Coarse Grain Tube Selection and Specifications

Material Composition Options

Composition 1651, featuring zirconia stabilized with 3.0% calcia by weight, is typically specified for high-temperature induction heated crystal growth furnaces. This composition delivers reliable performance through repeated cycling from room temperature to 2000°C. Other Zircoa compositions are available and listed below.

Manufacturing Options

Choose between pressed and cast configurations based on your specific requirements:

- Pressed tubes for applications requiring dimensional precision

- Cast tubes for complex geometries and specialized configurations

- Custom diameters, lengths, and grain sizes available

Typical Properties

Course Grain Tube Sizes

| OD | ID |

|---|---|

| mm / inches | mm / inches |

| 38.1 mm / 1.5 inches | 25.4 mm / 1.00 inches |

| 38.1 mm / 1.5 inches | 12.7 mm / 0.5 inches |

| 50.8 mm / 2.00 inches | 38.1mm / 1.50 inches |

| 50.8 mm / 2.00 inches | 31.7 mm / 1.25 inches |

| 50.8 mm / 2.00 inches | 25.4 mm / 1.00 inches |

| 63.5 mm / 2.5 inches | 50.8 mm / 2.00 inches |

| 63.5 mm / 2.50 inches | 44.4 mm / 1.75 inches |

| 63.5 mm / 2.50 inches | 38.1 mm / 1.50 inches |

| 69.8 mm / 2.75 inches | 57.1 mm / 2.25 inches |

| 76.2 mm / 3.00 inches | 63.5 mm / 2.50 inches |

| 76.2 mm / 3.00 inches | 50.8 mm / 2.00 inches |

| 88.9 mm / 3.50 inches | 76.2 mm / 3.00 inches |

| 88.9 mm / 3.50 inches | 63.5 mm / 2.50 inches |

| 92.2 mm / 3.63 inches | 79.5 mm / 3.13 inches |

| 101.6 mm / 4.00 inches | 88.9 mm / 3.50 inches |

| 101.6 mm / 4.00 inches | 76.2 mm / 3.00 inches |

| 114.3 mm / 4.50 inches | 101.6 mm / 4.00 inches |

| 127.0 mm / 5.00 inches | 114.3 mm / 4.5 inches |

| 127.0 mm / 5.00 inches | 101.6 mm / 4.00 inches |

| 152.4 mm / 6.00 inches | 139.7 mm / 5.50 inches |

| 152.4 mm / 6.00 inches | 127.0 mm / 5.00 inches |

| 177.8 mm / 7.00 | 152.4 mm / 6.00 inches |

| 190.5 mm / 7.50 inches | 171.4 mm / 6.75 inches |

| 222.2 mm / 8.75 inches | 196.8 mm / 7.75 inches |

| Composition | 1651 | 3001 | 3004 | 6105 | 0872 |

|---|---|---|---|---|---|

| Stabilizer | CaO | MgO | MgO | CaO | |

| Typical Chemistry | |||||

| SiO2 (wt.%) | 0.4 | 1.5 | 1.4 | 3.5 | 0.3 |

| CaO (wt.%) | 3.1 | 0.2 | 0.4 | <0.1 | 2.4 |

| MgO (wt.%) | 0.4 | 2.7 | 2.6 | <0.1 | 0.4 |

| Fe2O3 (wt.%) | 0.1 | 0.1 | 0.2 | 0.2 | 0.1 |

| Al2O3 (wt.%) | 0.4 | 0.8 | 0.9 | 94.3 | 0.3 |

| TiO2 (wt.%) | 0.1 | 0.1 | 0.1 | <0.1 | 0.1 |

| Y2O3 (wt.%) | N/A | N/A | N/A | N/A | N/A |

| Typical Physical Properties | |||||

| Density (g/cm3) | 4.2 | 4.6 | 4.6 | 2.8 | 3.8 |

| Porosity (%) | 25.0 | 18.0 | 16.0 | 18.0 | 33.0 |

| Cold MOR (Mpa) | 16.5 | 24.0 | 24.0 | 19.3 | 5.5 |

| Monoclinic (%) | 27 | 85 | 85 | N/A | 50 |

Optimize Crystal Growth with Backup Materials

Combine coarse grain tubes with our specialized backup materials for optimal thermal cycling performance. Our pre-sintered backup materials provide superior insulation and extend tube service life in demanding crystal growth applications.

- Backup 1859 — Grog, partially stabilized with magnesia and calcia

- Backup 1860 — Grog, partially stabilized with magnesia and calcia

- Backup GNF — Grog, partially stabilized with calcia

- Backup 10B — Bubble, partially stabilized with calcia

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Klaus Steuer

+49-611-335497-20