Brick

Home | Products/Applications | Specialty Refractory Products |

Standard and custom brick configurations for self-supporting furnace structures. Ideal for glass melting, quartz processing, carbon black combustion, and many other high-temperature furnace linings where thermal insulation, contamination prevention, and structural integrity are critical.

Product Applications

Thermal insulation is fundamental to effective furnace design, and refractory bricks form the structural foundation that determines overall system performance. Zircoa refractory bricks deliver exceptional thermal insulation properties combined with the structural integrity needed for demanding high-temperature applications up to 2000°C and beyond.

Our engineered brick systems provide the critical thermal barrier that maximizes energy efficiency, extends furnace life, and ensures consistent process temperatures. Whether for new construction or furnace rebuilds, proper brick selection and installation are essential for optimal thermal performance. Learn more about our refractory bricks below, or get in touch with our experts to discuss project specifics.

Advantages of Zircoa Refractory Bricks

- Superior thermal insulation for maximum energy efficiency

- Exceptional thermal shock resistance for reliable cycling

- High-temperature capability exceeding 2000°C

- Structural integrity for self-supporting furnace construction

- Engineered porosity optimized for insulation performance

- Chemical resistance against aggressive furnace atmospheres

- Dimensional stability under thermal stress

- Extended service life reduces maintenance costs

Primary Industries

- Glass melting and forming operations

- Quartz processing and high-purity applications

- Carbon black production facilities

- Crystal growth and semiconductor processing

- Refractory-metals operations

Key Applications

- Furnace wall construction and hot face linings

- Backup insulation layers for enhanced thermal efficiency

- Self-supporting structures in extreme temperature zones

- Thermal barriers for process temperature control

- Furnace rebuilds and maintenance applications

Refractory Brick Configurations and Selection

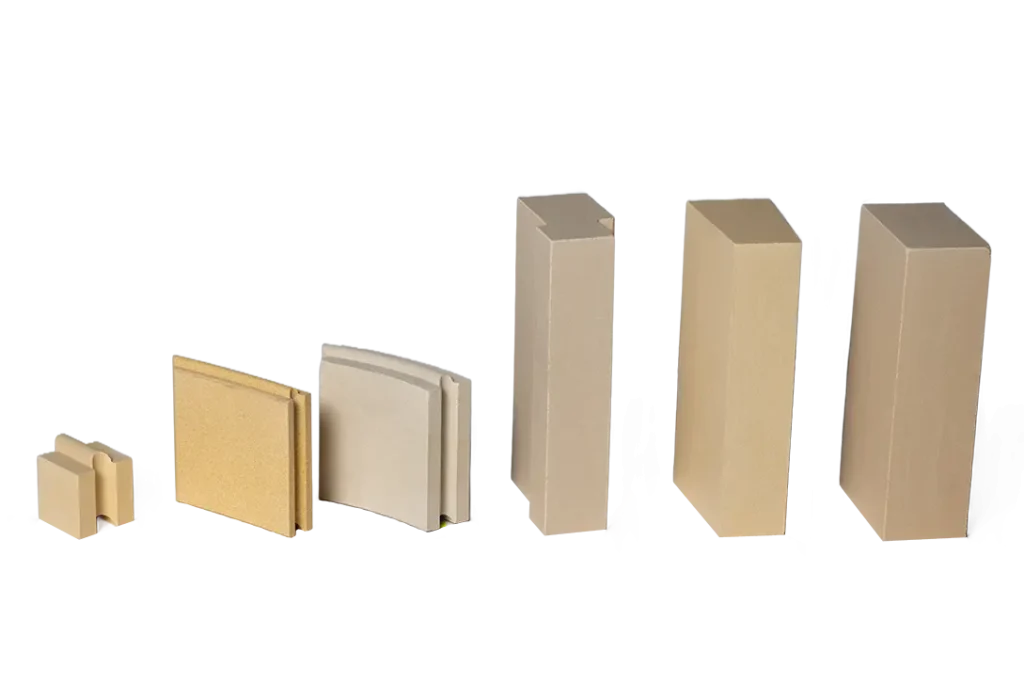

Standard and Tongue-and-Groove Options

We use Calcia, Magnesia, or Yttria stabilized zirconium oxide in standard, complex, and custom designs for enhanced structural integrity and thermal sealing.

Zircoa’s tongue and groove refractory bricks are designed for the building of self-supporting structures, making them ideal for high temperature cycling environments. Using tongue and groove brick eliminates line of sight radiation, and adds physical stability to the structure. Rings and circles, with an ID as small as 6″ can be achieved.

Standard refractory bricks are used primarily for custom high-temperature furnace linings, supports, and heat shields. Zircoa’s standard bricks withstand operating temperatures greater than 2000°C (3630°F) with capacity to spare.

Critical Design Considerations

Proper brick selection requires careful consideration of:

- Operating temperature requirements and thermal cycling

- Furnace atmosphere and chemical exposure conditions

- Structural load requirements and thermal expansion

- Installation methods and joint sealing requirements

Engineering Support

Our application specialists provide comprehensive support for furnace design optimization, brick selection, and installation best practices to ensure maximum thermal performance and service life. Use our ring calculator to help you determine the quantity of Zircoa 2″ high arch and straight tongue and groove bricks required to construct 6″ to 72″ diameter rings.

Typical Properties

| Composition | 1651 | 1968 | 2290 | 3004 |

|---|---|---|---|---|

| Stabilizer | CaO | CaO | Y2O3 | MgO |

| Typical Chemistry | ||||

| SiO2 (wt. %) | 0.4 | 0.7 | 0.3 | 1.4 |

| CaO (wt.%) | 3.1 | 3.5 | 0.3 | 0.4 |

| MgO (wt.%) | 0.4 | 0.1 | 0.1 | 2.6 |

| Fe2O3 (wt.%) | 0.1 | 0.1 | 0.1 | 0.2 |

| Al2O3 (wt.%) | 0.4 | 0.9 | 0.3 | 0.9 |

| TiO2 (wt.%) | 0.1 | 0.2 | 0.1 | 0.1 |

| Y2O3 (wt.%) | N/A | N/A | N/A | N/A |

| Typical Physical Properties | ||||

| Density (g/cm3) | 4.2 | 3.3 | 4.5 | 4.6 |

| Porosity (%) | 25.0 | 35.0 | 23.0 | 16.0 |

| Cold MOR (Mpa) | 16.5 | 16.5 | 24.0 | |

| Monoclinic (%) | 27 | 32 | 54 | 85 |

Optimize Thermal Performance with Backup Materials

Extend the life of your furnace and maintain better control over your furnace temperatures with Zircoa’s pre-sintered grog refractory backup. Options include:

Backup 1859 — Grog, partially stabilized with magnesia and calcia

Backup 1860 — Grog, partially stabilized with magnesia and calcia

Backup GNF — Grog, partially stabilized with calcia

Backup 10B — Bubble, partially stabilized with calcia

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Klaus Steuer

+49-611-335497-20