Setter Plates And Discs

Home | Products/Applications | Specialty Refractory Products |

Kiln furniture for firing electronic components including barium titanate capacitors, thermistors, and PZT piezoelectrics. Engineered to prevent contamination while withstanding repeated thermal cycles.

Product Applications

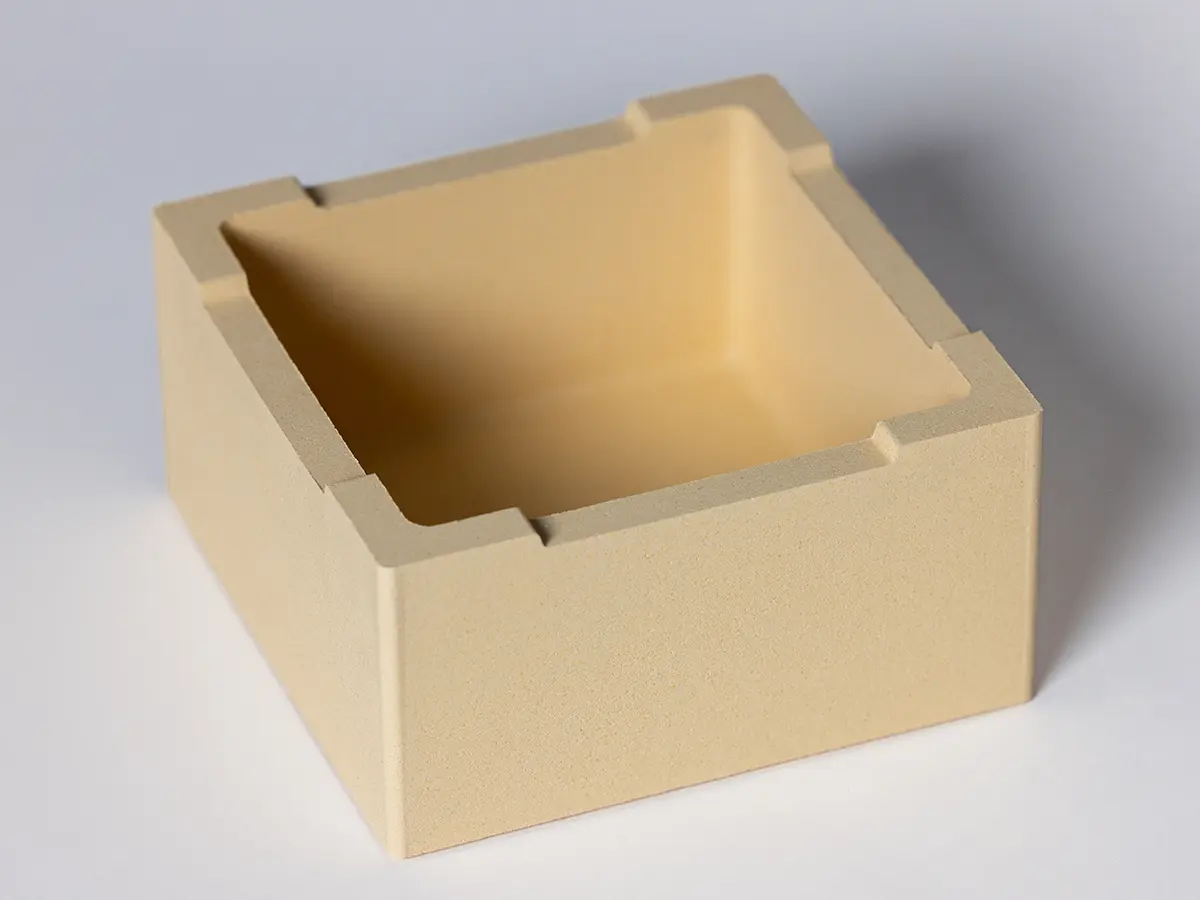

Setter plates and discs function as essential saggers and kiln furniture, providing stable holding vessels that support and position components during high-temperature firing processes. Zircoa setter plates deliver superior performance for firing electronic components including barium titanate capacitors, thermistors, and PZT piezoelectrics at temperatures above 1300°C with no material reaction or contamination.

These precision kiln furniture pieces are engineered to withstand repeated thermal cycles while maintaining dimensional stability and chemical inertness. Available in various standard dimensions or manufactured to your specific requirements, our saggers ensure consistent positioning and contamination-free processing for critical electronic components.

Learn more about our kiln furniture solutions below, or contact our specialists to discuss your specific setter plate requirements.

The Benefits of Zircoa Saggers and Kiln Furniture

- High-temperature capability above 1300°C with no material reaction

- Chemical inertness prevents contamination of sensitive electronic components

- Dimensional stability maintains precise positioning through thermal cycles

- Superior thermal shock resistance for reliable repeated use

- Non-reactive surface ensures component purity and quality

- Custom dimensions available for specific application requirements

- Extended service life reduces kiln furniture replacement costs

- Consistent performance for repeatable processing results

Primary Industries

- Electronic component manufacturing and assembly

- Capacitor and ceramic component production

- Semiconductor processing and advanced materials

- Medical device component manufacturing

- Precision ceramic and piezoelectric component production

Key Applications

- Barium titanate capacitor firing and sintering

- Thermistor manufacturing and heat treatment

- PZT piezoelectric component processing

- Multi-layer ceramic capacitor (MLCC) production

- Electronic ceramic component sintering and annealing

Setter Plate and Disc Selection

Standard and Custom Configurations

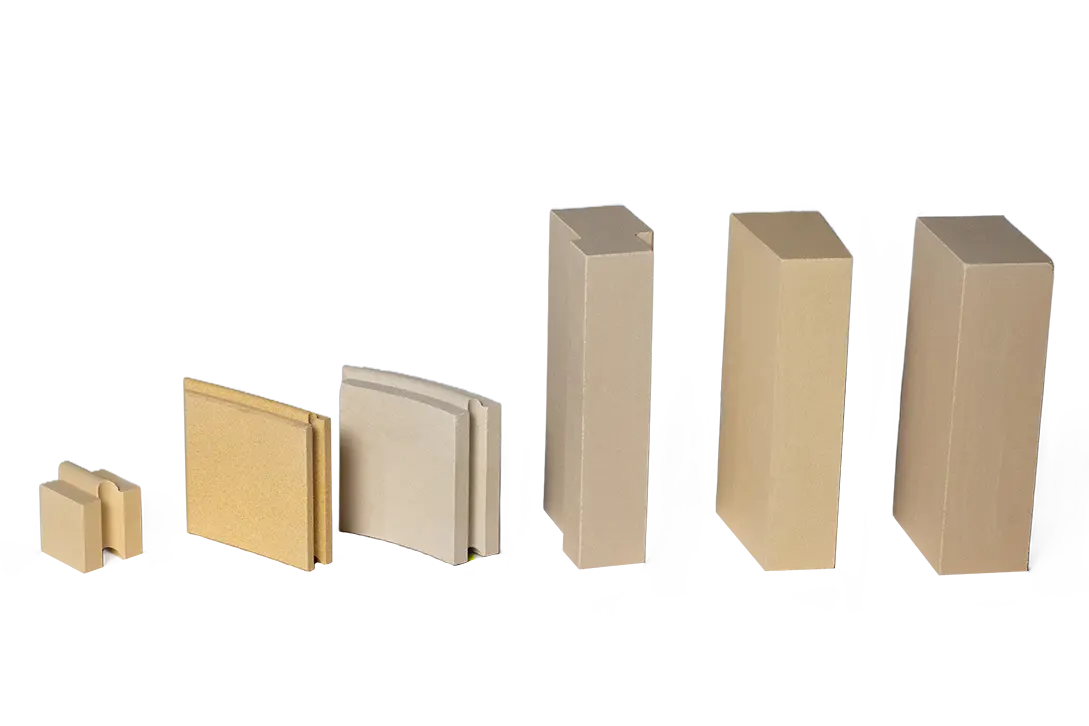

Our saggers and kiln furniture are available in multiple configurations to meet your specific needs:

- Flat round discs for standard component positioning

- Setter plates for larger component arrays

- Two-rail plates for specialized holding applications

- Custom dimensions and configurations for unique requirements

Saggers Material Selection Guidance

Composition 1661 is recommended for initial testing and is used by the majority of our customers. This -28 Tyler mesh partially stabilized zirconia provides optimal performance for most electronic component firing applications.

Typical Properties

| Part No. | Diameter (inches) | Thickness (inches) | Diameter (mm) | Thickness (mm) | Weight (lb) | Weight (g) |

|---|---|---|---|---|---|---|

| S-2943-.25 | 0.75 | 0.250 | 19.1 | 6.4 | 0.02 | 9 |

| S-2943-.50 | 0.75 | 0.500 | 19.1 | 12.7 | 0.04 | 16 |

| S-2256-.25 | 0.80 | 0.250 | 20.3 | 6.4 | 0.02 | 9 |

| S-2256-.50 | 0.80 | 0.500 | 20.3 | 12.7 | 0.04 | 18 |

| S-3780.25 | 1.0 | 0.250 | 25.4 | 6.4 | 0.03 | 14 |

| S-3780-.50 | 1.0 | 0.500 | 25.4 | 12.7 | 0.06 | 27 |

| S-3781-.25 | 1.5 | 0.250 | 38.1 | 6.4 | 0.07 | 32 |

| S-3781-.50 | 1.5 | 0.500 | 38.1 | 12.7 | 0.14 | 64 |

| S-3782-.25 | 2.0 | 0.250 | 50.8 | 6.4 | 0.13 | 59 |

| S-3782-.50 | 2.0 | 0.500 | 50.8 | 12.7 | 0.25 | 113 |

| S-3783-.25 | 2.5 | 0.250 | 63.5 | 6.4 | 0.20 | 91 |

| S-3783-.50 | 2.5 | 0.500 | 63.5 | 12.7 | 0.39 | 177 |

| S-3575-.25 | 3.0 | 0.250 | 76.2 | 6.4 | 0.28 | 127 |

| S-3575-.50 | 3.0 | 0.500 | 76.2 | 12.7 | 0.57 | 259 |

| S-3784-.25 | 3.5 | 0.250 | 88.9 | 6.4 | 0.39 | 177 |

| S-3784-.50 | 3.5 | 0.500 | 88.9 | 12.7 | 0.76 | 345 |

| S-3785-.25 | 4.0 | 0.250 | 101.6 | 6.4 | 0.50 | 227 |

| S-3785-.50 | 4.0 | 0.500 | 101.6 | 12.7 | 1.00 | 454 |

| S-3786-.25 | 4.5 | 0.250 | 114.3 | 6.4 | 0.70 | 318 |

| S-3786-.50 | 4.5 | 0.500 | 114.3 | 12.7 | 1.40 | 635 |

| S-3787-.25 | 5.0 | 0.250 | 127.0 | 6.4 | 0.80 | 363 |

| S-3787-.50 | 5.0 | 0.500 | 127.0 | 12.7 | 1.60 | 726 |

| S-3788-.375 | 6.0 | 0.375 | 152.4 | 9.5 | 1.70 | 771 |

| S-3788-.50 | 6.0 | 0.500 | 152.4 | 12.7 | 2.40 | 1089 |

| S-3529-.375 | 7.0 | 0.375 | 177.8 | 9.5 | 2.31 | 1048 |

| S-3529-.50 | 7.0 | 0.500 | 177.8 | 12.7 | 3.10 | 1406 |

| S-3790-.375 | 8.0 | 0.375 | 203.2 | 9.5 | 3.02 | 1370 |

| S-3790-.50 | 8.0 | 0.500 | 203.2 | 12.7 | 4.02 | 1823 |

| S-3812-.375 | 10.0 | 0.375 | 254.0 | 9.5 | 4.72 | 4250 |

| S-3812-.50 | 10.0 | 0.500 | 254.0 | 12.7 | 6.30 | 4250 |

Setter Plates and Two Rail Plates Sizes

| Part No. | Length (inches) | Width (inches) | Thickness (inches) | Length (mm) | Width (mm) | Thickness (mm) | Weight (lb) | Weight (g) |

|---|---|---|---|---|---|---|---|---|

| S-3406-.25 | 4.0 | 4.0 | 0.250 | 101.6 | 101.6 | 6.4 | 0.64 | 291 |

| S-3406-.50 | 4.0 | 4.0 | 0.500 | 101.6 | 101.6 | 12.7 | 1.28 | 581 |

| S-3460-.25 | 4.5 | 4.0 | 0.250 | 114.3 | 101.6 | 6.4 | 0.7 | 327 |

| S-3460-.50 | 4.5 | 4.0 | 0.500 | 114.3 | 101.6 | 12.7 | 1.44 | 654 |

| S-3810-.375 | 6.0 | 6.0 | 0.375 | 152.4 | 152.4 | 9.5 | 2.16 | 980 |

| S-3810-.50 | 6.0 | 6.0 | 0.500 | 152.4 | 152.4 | 12.7 | 2.88 | 1308 |

| Part No. | Length (inches) | Width (inches) | Thickness (inches) | Rail H. (inches) | Length (mm) | Width (mm) | Thickness (mm) | Rail H. (mm) | Weight (lb) | Weight (g) |

|---|---|---|---|---|---|---|---|---|---|---|

| S-284-.25 | 4.50 | 2.375 | 0.25 | 0.125 | 114.3 | 60.3 | 6.4 | 3.2 | 0.4 | 182 |

| S-603-.25 | 4.50 | 2.375 | 0.25 | 0.25 | 114.3 | 60.3 | 6.4 | 6.4 | 0.5 | 236 |

| S-4324 | 5.91 | 5.91 | 0.375 | 0.25 | 150 | 150 | 9.5 | 6.4 | 2.1 | 950 |

| Composition | 1651 | 1661 |

|---|---|---|

| Stabilizer | CaO | CaO |

| Typical Chemistry | ||

| SiO2 (wt.%) | 0.4 | 0.4 |

| CaO (wt.%) | 3.1 | 3.0 |

| MgO (wt.%) | 0.4 | 0.3 |

| Fe2O3 (wt.%) | 0.1 | 0.1 |

| Al2O3 (wt.%) | 0.4 | 2.1 |

| TiO2 (wt.%) | 0.1 | 0.1 |

| Y2O3 (wt.%) | N/A | N/A |

| Typical Physical Properties | ||

| Density (g/cm3) | 4.2 | 4.1 |

| Porosity (%) | 25.0 | 27.0 |

| Cold MOR (Mpa) | 16.5 | 33.0 |

| Monoclinic (%) | 27 | 30 |

Complete Kiln Furniture Solutions

Access our comprehensive technical resources including application guides, installation procedures, recent news, and downloads related to zirconia products and Zircoa. Our engineering team provides ongoing support to ensure contamination-free processing and consistent results for your electronic component manufacturing. Know exactly what you need? Visit our product and application filtering portal here.

Related Case Studies

There are currently no case studies available for this product.

Contact a specialist

USA & Worldwide

Kyle Borgmann

+1-440-384-9717

Europe, the Middle East, Africa & India

Thomas Boehm

+49-611-335497-22